Vanadium Redox Flow Batteries for Long Duration

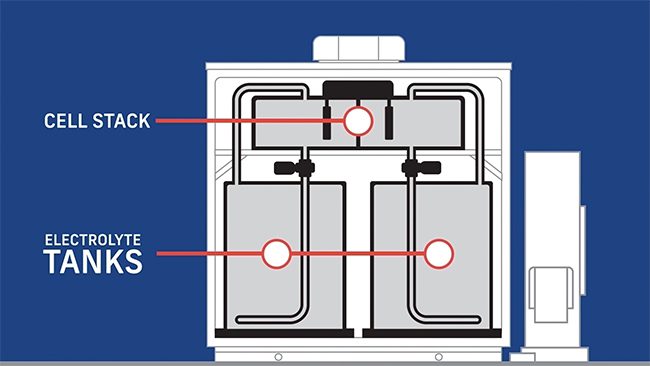

While a lead BESS is a good fit for short-duration energy needs, climate change and aging infrastructure demand that we also be prepared with both grid storage and backup power for longer durations, using battery chemistries that offer the same, or greater, recyclability. A newer technology, vanadium redox flow batteries (VRFB, Figure 1), shows great promise. VRFBs are capable of discharging energy continuously for four to 12 hours at a time, making them an ideal solution for hospitals and military bases—institutions where continuous power is critical.

|

Column 1 |

| 1 |

|

| 2 |

1. Vanadium redox flow batteries (VRFBs) include a cell stack and two electrolyte tanks, among other equipment. VRFBs offer extended cycle life, high stability and durability, non-flammable chemistry, modular and scalable construction, and long-duration energy storage (four hours or more). Courtesy: Stryten Energy

|

With proper maintenance, VRFBs can last more than 20 years without its electrolyte losing storage capacity. This longevity complements the lifespan of wind and solar installations. The electrolyte itself is infinitely recyclable, and the battery offers a near-limitless cycle life. In addition, VRFBs avoid some of the safety concerns inherent in other chemistries. The aqueous-based chemistry is thermally safe, allowing large systems to be placed close together. With so many properties that make VRFBs a safe, reliable, and sustainable option, they’re a good fit for storing and deploying the vast levels of clean energy the U.S. will need to provide greater grid stability.

Because the technology is cutting-edge, there is still work to be done to establish a domestic supply chain and scale manufacturing for the key components of VRFB systems, specifically vanadium electrolyte. The best practices of the lead battery industry in the U.S. can serve as a blueprint for the anticipated rapid growth of VRFB markets.

Improved supply chain protocols, combined with the typical savings from economies of scale, are prime examples of how the best practices of the lead battery industry can help rapidly drive prices of the vanadium electrolyte down to be more in line with market expectations for BESS costs. The lead battery industry also has extensive vertically integrated capabilities, from engineering to manufacturing, to sales and marketing, to operations and maintenance services, as well as its robust circular economy. As vanadium electrolyte production levels increase to meet demand, volumes could not only meet, but far exceed levels of the lead battery industry. Vanadium electrolyte suppliers will need to engage in similar practices.

BESS in Action

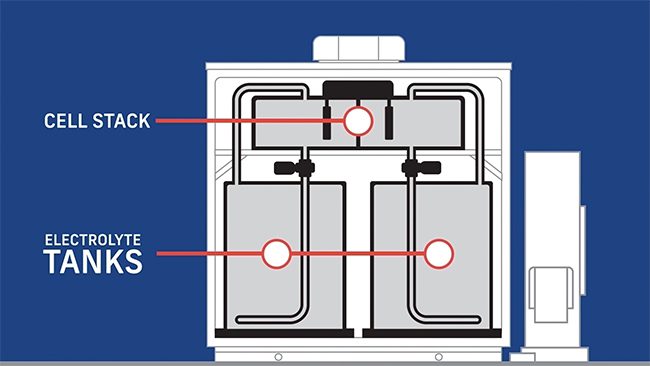

To not only understand VRFB’s energy storage and shifting capabilities, but also identify additional use cases, energy storage solution providers are partnering with communities across the country to deploy these systems in real-world situations. Stryten Energy partnered with Snapping Shoals EMC (Electric Membership Corp.), a Georgia-based utility provider for one of the fastest-growing regions in the nation, to test VRFB with its more than 100,000 resident and business customers (Figure 2). The project was the first VRFB energy storage system manufactured and installed in Georgia. Snapping Shoals’ 20-kW/120-kWh system was commissioned in August 2023, and the teams are comparing results and learnings from the project.

|

Column 1 |

| 1 |

|

| 2 |

2. Snapping Shoals EMC (Electric Membership Corp.), a consumer-owned, non-profit cooperative with headquarters in Covington, Georgia, installed an advanced VRFB to demonstrate and evaluate its capabilities. The project was the first VRFB energy storage system manufactured and installed in the state of Georgia. Courtesy: Stryten Energy

|

A lead BESS project is currently underway for a local community center, connecting a 100-kW/322-kWh BESS to a new microgrid, solar array, and the legacy power grid. The new microgrid will enable the location to serve as a resiliency center for the community to gather and have critical needs met in the event of grid outages. The center will provide local residents with a place to go for a hot meal, to provide relief from extreme temperatures, or to store temperature-sensitive medication in a safe place. Stryten’s advanced lead batteries are well-suited to the high reliability and safety requirements necessary to have the BESS idle for long periods of time, but ready to perform when the critical need arises.

Stryten is also collaborating with a leading university to fine-tune its advanced battery technology. A lead BESS and a VRFB BESS are being placed as a “living laboratory” to further develop the products and applications. Some of the goals of the living lab include exploration of next generation gas stations, where solar arrays plus BESS microgrids provide carbon-free, cost-effective pathways for electric vehicle charging. The systems will also fuel studies on how to deploy BESSs most effectively for resiliency centers to support the mission of sustainability and resiliency for the campus.

Planning for Short- and Long-Duration Needs

The need for clean energy storage is well-established, and the resources are in place to refine BESS technology and capitalize on economies of scale. The onus is now on energy innovators to improve tried-and-true lead battery technology and experiment with new chemistries such as vanadium to meet the wide range of duration needs.

Battery manufacturers should leverage best practices from the circular economy of the lead battery industry to ensure a strong domestic supply chain. It will take a variety of battery chemistries to power the world of tomorrow, and by investing in U.S. manufacturing and supply chains for sustainable BESS technologies, the infrastructure that makes that resilient, clean energy-driven future possible can be built.

—Scott Childers is vice president of Essential Power at Stryten Energy.

!

1.1¢

!

1.1¢

(20min delay)

(20min delay)