sheet metal duct fabrication 16 Times

sheet metal prototyping 1 Time

sheet metal ductwork fabrication 1 Time

duct fabrication 13 Times

ductwork manufacturing 1 Time

air duct fabrication 1 Time

Metal ducts are critical elements for the optimum functioning of the HVAC systems in buildings. They provide adequate flow and diffusion in the areas of living and working. The formation of these ducts needs special attention and skilled work to maintain the best circulatory flow. Selecting the right materials and processes greatly impacts performance and product life.

This guide focuses on common processes for sheet metal duct construction. Learn the design process and ways of choosing materials and get acquainted with the basics of ductwork manufacturing.

Sheet Metal Ductwork Fabrication Overview

Sheet Metal Duct

A sheet metal duct fabrication consists of some parts. The design may differ depending on the specific application requirements. When assembling HVAC accessories, you create a complete duct network. First, let’s examine what a duct is in HVAC systems before proceeding to the design process.

What is a Duct in HVAC?

HVAC Duct

A duct is a passageway in a pipe, tube, or channel. It is utilized for the passage of air in HVAC systems. Simply put, by joining these ducts with accessories, you end up with a total ductwork system.

Types of Sheet Metal HVAC Ducts

HVAC sheet metal duct fabrication generally falls into two categories:

●Flexible Ductwork: These ducts are flexible and therefore suitable for places where bending is required. They include; wire or coil types which are made of pliable material.

●Rigid Ductwork: These ducts are rigid and are mainly available in rectangular or cylindrical cross-sections.

Focus on Sheet Metal Ducts

HVAC systems require sheet metal duct fabrication. The main types of sheet metal ducts include:

1. Round Sheet Metal Duct

Round Duct

Round ducts are preferred particularly due to their airflow characteristics. Their shape is smooth, and circular, which minimizes air drag, and thus is suitable for most HVAC systems.

Key benefits of round ducts include:

●Reduced pressure drops

●Improved airflow efficiency

●Less dirt build-up and hence less bacteria growth

●Superior acoustic performance

●Minimum chance of having to use extra insulation

2. Rectangular Sheet Metal Duct Fabrication

Rectangular Sheet Metal Duct

Rectangular ducts are preferred based on installation factors and space requirements. Since they are easier to install than round ones. These ducts are flexible and used for large HVAC systems that need a particular form of duct.

These ducts have adjustable width and height and are described by their width-to-height ratio called aspect ratio. The ideal aspect ratio should not be more than 4. Ducts with higher ratios:

●Use more material

●Experience higher pressure drops

●Increased sealing complexity

3. Spiral Sheet Metal Duct Fabrication

Spiral Duct

Spiral ducts are specifically designed to be strong, and capable of withstanding a lot of use. It has a helical structure, which gives it strength, and is mainly applied in places with concerns to air movement.

4. Oval Ducts

Oval Duct

Besides, there are other types of oval ducts. However, they are not commonly used as round ones. Although they offer some advantages, they come with specific challenges:

●Challenges in procurement and production of accessories

●The difficulties in dealing with larger sizes

●Increased pressure could make the duct to adopt a more circular cross-sectional area

●Challenging to join when a large aspect ratio is needed

●In the case of a change from round to rectangular or vice versa, it’s important to take into consideration equivalent diameter (the diameter of a round duct, normally achieves the same pressure drop as a rectangular duct)

Sheet Metal Duct Fabrication: Design Considerations

Sheet metal duct design determines the cost, ease of production, and general functionality of the final ductwork. Hollow sheet metal ducts for HVAC or air duct fabrication systems require the following factors to be considered when designing.

1. Airflow Characteristics

Duct Heating Air System

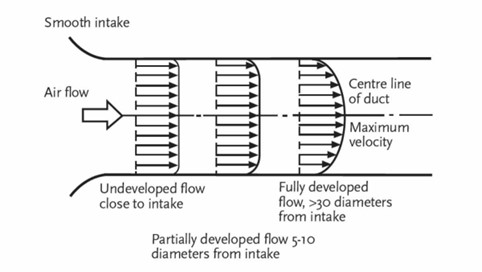

The type of airflow can be an important consideration when designing HVAC ducts. It affects the flow characteristics and the overall performance of the duct system.

Key parameters to evaluate for sheet metal duct fabrication include:

●Airflow Volume: It is measured in cubic feet per minute (CFM), which shows how much air flows through the system.

●Duct Size: The duct dimensions are calculated in square footage.

●Air Velocity: The velocity of air moving in the duct usually expressed in feet per minute (FPM).

Additional airflow characteristics to analyze for sheet metal duct fabrication include:

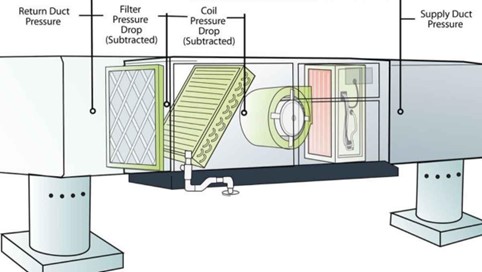

●Pressure: It’s necessary to evaluate both the incremental and the absolute duct pressure.

●Air Density: The air density has implications for airflow computations and duct dimensions.

●Static, Total, and Velocity Pressure: These parameters give information concerning the resistance and pressure fluctuations in the duct system.

Through these characteristics, it is possible to correctly size and design the duct system for the desired operation.

2. Duct Components

Basic Duct Components

A sheet metal duct system comprises various parts. Each part is extremely significant in the ductwork and must be appropriately incorporated with other HVAC accessories.

These components include:

●Duct Boots

●Duct Adapters

●Duct Angles

●Duct Caps

●Duct Cleats

●Duct Collars

●Duct Corners

●Duct Couplings

●Duct Elbows

●Duct Reducers/Expanders

●Duct Plenums

●Duct Tees

●Duct Wyes

●Air Return Boxes and Frames

●Duct Transitions

All the above-mentioned components influence the general layout of the building as well as the airflow patterns. The effective and appropriate identification combined with the integration of these components guarantees optimal system operation.

3. Duct Classification

Pressure Classification of HVAC Duct

Ducts can be classified based on different criteria:

●Velocity Classifications: Ducts may be classified according to their velocity levels: high-velocity, medium-velocity, or low-velocity ducts determine the design and the material used.

●Pressure Classifications: These systems are classified into low pressure, medium pressure, and high pressure depending on the pressure range designed to work under.

4. Sizing the Duct for HVAC

HVAC Duct Sizing Parameters

It’s advised to correctly measure the ducts to allow the right distribution of air and effectiveness in the operations of heating and cooling systems. Duct sizing is done in various ways, each provides a unique way to determine the right amount of airflow, pressure, and energy used. The main methods for sizing HVAC ducts are:

Equal Friction Method

The equal Friction Method provides a constant friction loss per unit length of duct. It’s commonly used in applications, which require equitable resistance of airflow throughout the duct system.

Velocity Reduction Method

In this approach, the velocity of air is low as it passes through the system so that pressure losses are minimized. It is beneficial for systems that require low noise levels and moderate airspeed as a means to an end.

Static Regain Method

The intended approach can be used to lower fan energy intensity by restoring pressure as air passes through the system. It is usually applied in long duct systems to cut energy expenses and maximize effectiveness. The general principles of duct sizing are met, but with sheet metal duct design, there are many details to consider.

If you’d like to explore duct sizing in more depth, here are some useful resources:

●Duct Sizing – A Step-by-Step Guide – CED Engineering

●Duct Design Information – By David Jones

●How to Size Duct System – Super Cool

●Sizing the Ducts – Energy Vanguard

●Design of Air Ducts – Arlan Burdick

●HVAC Duct Sizing Calculator – Pick HVAC

●Duct Sizing and Calculation – The Engineering Mindset

Selecting the Right Sheet Metal Duct Material

Galvanized steel and aluminum are often used in sheet metal duct fabrication. However, other metals can be used for certain applications where conditions call for such use, for example, high temperatures or corrosive atmosphere.

Here are the key materials to consider for sheet metal duct fabrication for the HVAC system:

1. Galvanized Steel

Galvanized Steel Metal Ducts

Galvanized steel is most frequently used in industrial and residential HVAC systems. It features excellent corrosion properties and strength.

You can choose from two common types:

●ASTM A653

●Coating C90

Hot dip galvanized steel is a relatively cost-effective material for most applications, as it offers good durability under standard conditions.

2. Aluminum

Aluminum Air Duct

Aluminum is lightweight, self-healing, and ideal for clean rooms and locations where the air is laden with moisture like exhaust systems. Usually, It is used in decorative ducting in aesthetic heating and cooling systems.

Common aluminum alloys for sheet metal duct fabrication or ductwork include:

●ASTM B209

●1100 Series

●3003 Series

●5052 Series

3. Stainless Steel

Stainless Steel Duct

Stainless steel is non-corrosive, and thus most entities like kitchens or areas of high humidity prefer it. Stainless steel ducts are common in commercial and industrial HVAC systems.

Recommended grades for stainless steel ducting:

●ASTM A167

●Class 302/304

4. Copper

Copper HVAC Duct

Copper ducts are preferred for specific HVAC systems, and are used in chemical companies or for aesthetic purposes. A breathable metal, copper has immense flexibility, thermal conductivity, and antiseptic qualities; ideal for specific exhaust systems. Copper ducts are not so common in day-to-day utilization but they are perfect for certain, high-velocity deployments.

5. Carbon Steel

Carbon steel is used in high-temperature HVAC systems. It may need a special coating to improve its corrosion resistance.

When selecting material for your HVAC ductwork, you need to evaluate the characteristics of the particular application such as corrosion, temperature, and fabrication cost. Out of these factors, you will be better able to select the right material for your system.

Sheet Metal Duct Fabrication Techniques

In general, the creation of the metal ductwork may differ slightly with the type of duct and its position. However, most are alike in fundamental steps; much variation is in the formation of the ducts.

Now, let’s learn more about duct sheet metal prototyping.

1. Round Sheet Metal Duct Construction

The formation of round sheet metal ducts can be done in several methods. Below are two common methods:

Manufacturing Spiral Metal Ducting

The process is frequently employed for the fabrication of strong spiral ducts. The steps involved include:

●Choose the material: Choose the right sheet metal, it can be aluminum, stainless, or galvanized steel.

●Cut the sheet metal: Since the duct designs differ, cut the sheet metal into strips to fit the design of the duct.

●Feed the strip into a spiral duct-making machine: The machine has both internal and external welding works. While feeding the metal strip through, the strip forms a spiral-like shape in the process of welding the edges. This forms a continuous spiral duct as the system continues around the building.

Spiral duct-making machines are highly efficient and capable of fabricating spiral ductwork in one single cycle.

Construction of Round Metal Duct without Spiral Lock Seam

The process for fabricating round metal ductwork without a spiral lock seam is as follows:

●Choose the material: Stainless steel, aluminum, or galvanized steel are some of the materials used in the construction of the frameworks.

●Cut the sheet metal: After optimal material selection, use the laser cutter, plasma cutter, or other shearing technique to cut the metal as the drawing indicates.

●Form the sheet metal into a circle: Make a ring-like shape from the cut metal and just leave a small portion for welding.

●Weld the two ends: The two ends of the sheet metal are butt joined by welding to form a round duct. On the other hand, if the sections are to be joined, a seam can be made on that part.

2. Oval Duct Fabrication

The oval duct fabrication process is quite similar to the round duct process. Here’s a depiction how the oval duct fabrication process.

●Create a round duct at the beginning of the construction process.

●The round duct is molded first, and then the duct is stretched by using a particular machine to get the oval cross-section.

●The process is an evolution of the round duct, adapted to the needs of the HVAC system.

3. Construction of Rectangle and Square Sheet Metal Ducts

The major difference between the fabrication processes of rectangular and square ducts is the size. Here's a step-by-step breakdown:

●Choose the material: Rectangular and square ducts are made from galvanized steel, aluminum, copper, and stainless steel.

●Cut the sheet metal: You can employ a laser cutter or plasma cutter to transform the metal into the right size. Normally, one requires two sheets of sheet metal to construct the duct.

●Form the sheet metal into "L" shapes: Shape the metal into an “L-like” form, with one side overlapping the other to form a joint.

●Join the pieces: Two of the pieces in the form of “L” are fastened together with rivets or welded. The joint has to be positive and can be made by sliding the hemmed section and locking it with screws or any other means.

Sheet Metal Duct Fabrication - Surface Quality Checkups

In the process of sheet metal duct fabrication, the following considerations are important for approval of the duct for use or commercial purposes.

1. Surface Finishing

When you construct the metal duct, the right surface finish should be applied to increase the product’s life and adapt to certain conditions.

Some commonly used surface finishes include:

●Painting: Predominantly used as decorative and in areas that require intense protection against rusting.

●Polishing: It makes the duct look better and increases its ability to resist dirt and grime.

●Powder Coating: Creates a hard, tough, anti-corrosive, anti-fade, and anti-scratch barrier with the surface.

●Sandblasting: Applied to wash the surface to obtain the required roughness for a specific purpose.

Treatments of sheet metal surface

2. Quality Testing

For sheet metal ducts fabrication it’s important to put the ducts through several tests to determine their efficiency and conformity to set standards.

Key quality checks include:

●Uniform Surface Finish: Ensure that the entire face of the duct has an equal layer of the desired coating.

●Consistent Dimensions: Check whether the duct is of the required dimension and if no further improvements are required at all.

●Welded Joints Quality: Examines the torsional characteristics of the welded structure to verify that the connections themselves are strong enough with no leakage.

●Surface Roughness: Checks that the surface texture of the casting is within acceptable limits to avoid, in the future, problems concerning airflow.

●Leakage Test: Evaluates the prospective duct for compliance with leakage which is a significant issue in the efficiency and safety of a home.

●Compliance with Safety Standards: Check that the duct meets the required safety and quality standards of the region.

Summary

To sum up, the sheet metal duct fabrication process involves planning, designing, achieving the right dimensions, right material selection, and finally choosing the right manufacturing technique. When appropriate tools and professional help are employed, ductwork fabrication can be an easy affair, and the ducts produced are very efficient.

- Forums

- ASX - By Stock

- An Ultimate Guide To Sheet Metal Duct Fabrication Process