I wouldn't profess to be a mining engineer, Remy, but I’ll have a stab. It all seems pretty standard to me although it was twenty years ago that I was a miner. Since then it’s been all tunnelling which is a same/same but different scenario If you know what I mean. But basically you decline down beside the ore body then branch out cross cuts to the ore, then you’re on the gravy train..your ore drives .. keep going north south or east west as the case may be, as long as she stays rich or as far as you’re allowed to go. Boffins will be making constant cost benefit analysis here . If grade falls away you know you’ve got more of the same underneath.. Keep the cork screw going down and do it again, rinse and repeat ..after a few levels you’re gonna start stoping operations which involves starting at one end and drilling your long holes between the levels.. To do this you used to get a rise miner with an airleg rockdrill ( that’s very old school now though ) more likely a raise bore driller these days will make a pilot hole between the levels at the end of the drives. Then Orica or the Swedish equivalent will come in and charge all of that up with emulsion explosive. When you make it go bang the holes right beside your raise bore hole go first ( so the rock has somewhere to go, otherwise it won’t work ) then all the holes along your ore drive, that you’ve spent maybe months drilling go off in series milliseconds apart from the first ones all the way back to the cross cut..These stopes give you mega tonnes and it’s all paydirt.. That’s what I mean by it target’s the ore really well..I’ve performed exploration drilling on the bottom level of a mine in Kambalda that was 1km vertically down from the surface! Can you imagine how big of an open cut hole you would have to dig to get to that ore. A huge underground stope is an awesome site to behold and HOLY f*! There’s nothing like the buzz you get from a stope blast going off.. I remember that it used to shake the bejeezus out of Leonora like an earthquake. You cannot under any circumstances enter an open stope, you will quite often see huge rocks the size of a Toyota hilux hanging from an old twisted split set rock bolt that you installed as ground ground support in the backs or roof of the drives when you excavated them it's a very dangerous and prohibited place to be. You use a low loader or ‘bogger’ operated by remote control to load it all out, and once you have, you wall up the stope from the floor to the brow and use spoil from the decline, cross cuts and vent shafts etc as stated on that page to make ‘a cemented paste tailings backfill used to maximise stope extraction rates. Figure 2 shows the detailed mine design used in the mining study”. Basically it helps shore it all up to keep you safe as you go, the more big massive holes you have in an underground mine the more the rock relaxes everywhere and as you can probably imagine you really don’t want that. Shout out to anyone who was working at Bronzewing gold mine in 2000 as I was and knows why you don’t try to reinvent the wheel with this part of the process.. But I digress.

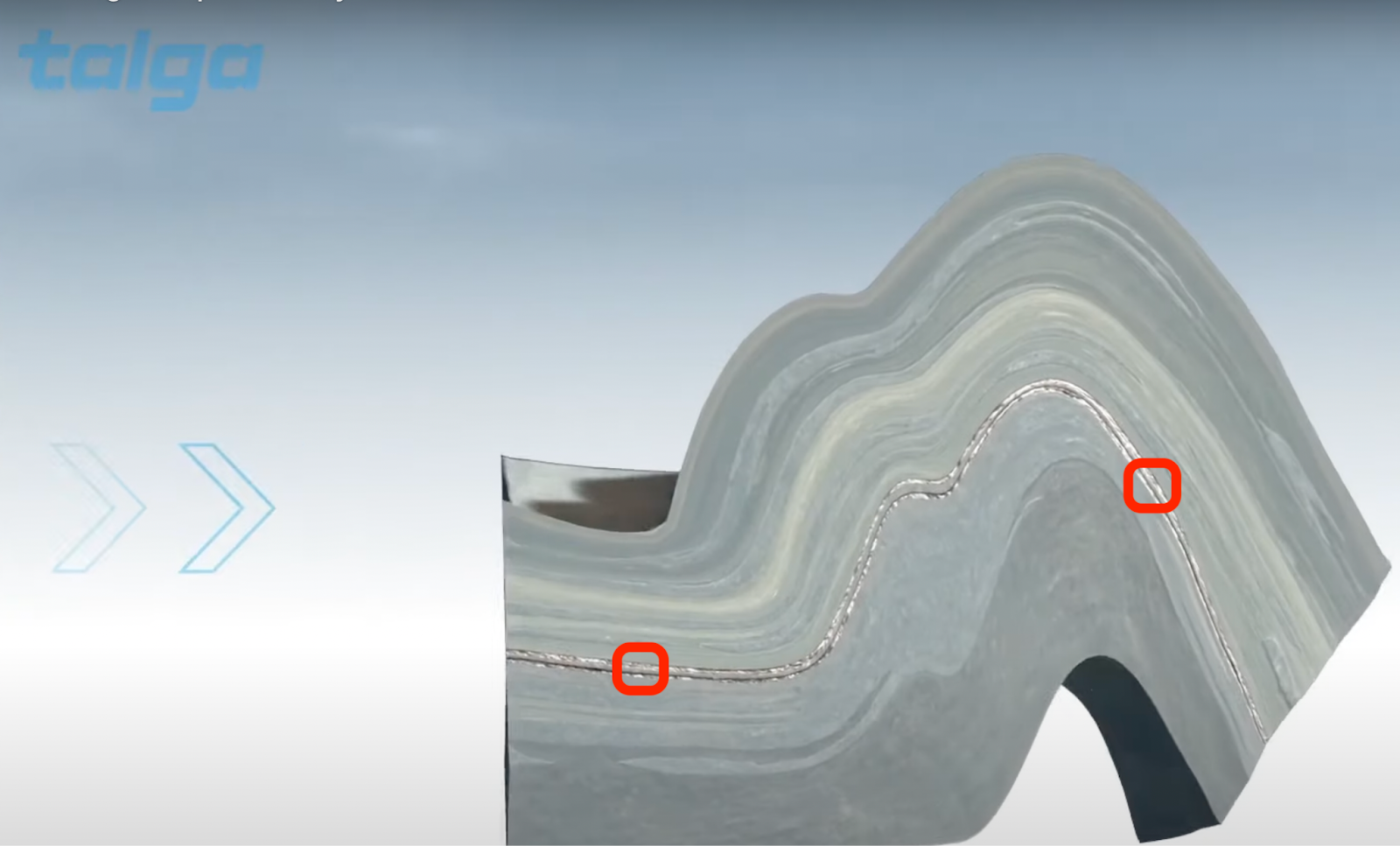

The footwall and hanging wall stuff sounds more technical than it really is.. Basically if you imagine the rock is in bedding layers that are never level and often times can be on quite steep angles… therefore on any drive one side will have that grain, if you will, coming downwards from above hanging into your drive ( the hanging wall ) and one has it all angling downward into the rock away from you ( The foot wall ) The hanging wall is the dangerous one really, that's the one you’re gonna worry more about big slabs falling out and possibly on top of you, your machinery or basically f*ing up your progress and causing huge delays, so they’re basically letting and anyone interested in this technical shit here the best and safest stoping method they think they’ll to employ.

Imagine that the red square on the right is running away from us here along our super rich seam for, let's say 400m, you’re gonna be worried about the left side of that drive it will be ‘the hanging wall’ as we look at it, It will quite probably be much more a challenge from a ground support perspective from the drive I’ve placed on the left, It may require bolts and mesh from the backs down to your shoulder height and might have to be shotcreted, the Swedes probably shotcrete the lot in time I would imagine. The drive on the left while still having a hanging wall on the left shouldn’t give you as much trouble.

At the start of my stint as a miner I was travelling around doing the diamond core sample drilling underground on the little Boart Longyear rigs. This is what turns your inferred resource to known, it’s exactly the same as what the Swedish drillers have done from the surface to give us our known resource to this date. It’s just done on smaller gear from the lower levels of the mine and you’re not going through the financial and time cost of doing it from the surface.

Mate I don’t know if this post is at all what you were asking, if it’s been helpful to you or others, or if this has been incredibly long and boring, but it’s been a trip down memory lane for me and it’s certainly been a while since I’ve made this big of a mental effort on a Sunday night for a post on Hotcopper. I hope someone gets something out of it, I’ve quite enjoyed doing it anyway.. I just really hope it makes some sort of sense. I’m wrapping it up now to watch the Motto GP. Let’s hope it does turn out to be a big week for us Talgarians as some are suggesting it might... Fingers crossed.

DYOR etc etc

(20min delay)

(20min delay)