Hi JM

Only just looking into this and there seem to be various different technologies out there.

I know HZR have developed a process for manufacturing hydrogen gas and high-purity graphite from natural gas and iron ore. You can read up one their process here http://www.hazergroup.com.au/

I noticed that Athena Resources, who own Byro Iron Ore project, have mentioned this process (see below)

EDE have a different technology they call Hythane, being trialled in India.

Australia recently signed a deal with Japan to ship liquid hydrogen from Victoria by 2020 - but I think that's being produced from brown coal in the Latrobe Valley

http://www.ibtimes.com.au/australia-signs-contract-japan-ship-hydrogen-1539612

Norway were looking into the possibility of hydrogen production on offshore platforms in Norway using freely available sea water - not sure how far they got

https://link.springer.com/article/10.1007/s40095-014-0104-6

http://www.hydrogenaustralia.org/

Re Tesla's roof tiles - yes they look great - I wouldn't mind having them on my roof. According to AFR article.....

Tesla will begin with production of two of the four styles it unveiled in October: a smooth glass and a textured glass tile. Roofing a 2000 square-foot (186 sq m) home in New York state — with 40 per cent coverage of active solar tiles and battery backup for night-time use — would cost about $US50,000 after federal tax credits and generate $US64,000 in energy over 30 years, according to Tesla's website calculator.

Read more: http://www.copyright link/business/...ough-to-be-huge-20170510-gw24hl#ixzz4grKMNMHK

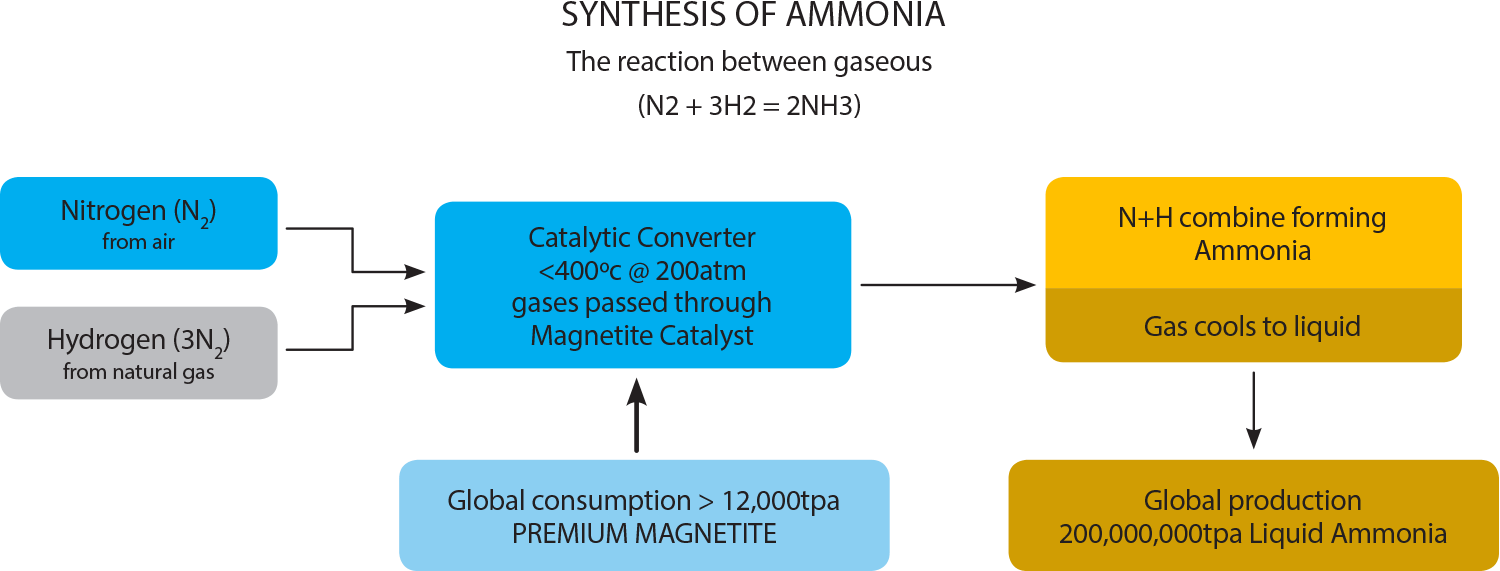

Catalyst in Ammonia Production

A premium is paid for magnetite used in the synthesis of ammonia which relies on a particularly contaminant free product with maximum surface area for nitrogen absorption. Magnetite is the most economic reagent used as a catalyst in ammonia production in over 400 production plants around the globe which collectively produce 200,000,000 liquid tonnes of ammonia a year.

Ammonia production increases in proportion to global food demand and is directly linked to population growth. Current annual consumption of magnetite in the global ammonia industry is estimated to be 100,000 tpa based on a magnetite requirement of one tonne of catalyst per 2000 tonnes of liquid ammonia produced. Ammonia production capacity is expected to rise from current 200M tpa to 250M tpa by 2018, according to Department of Primary Industries and research data and RnR Market Research. There is a 25,000tpa space through growth in this market for a competitive low cost, coarse grain, high purity product. On the basis of purity, grade and cost there is also a potential share in current markets.

Liquid Hydrocarbon Fuel Production from Coal and Natural Gas

Liquid fuel production is a similar technology in principal to ammonia, using a magnetite iron catalyst but focused on producing a synthetic hydrogen fuel from either natural gas or gasified coal. Production of this hydrocarbon fuel utilizes high pressure, high temperature reactors which operate upon a blend of micronized coal, a magnetite catalyst, and steam. The temperature of the reactor is raised to a level to efficiently convert the coal and steam into hydrogen and carbon monoxide then combing to form hydrocarbons. This is a growing industry and a relief valve for future liquid fuel supply. Supply growth of 25,000tpa of magnetite consumption into global synthetic fuel production is similar in volume to the ammonia industry at present and it is expected to increase in proportion to the perceived depletion of liquid fossil fuel stock.

- Forums

- Commodities

- Renewable hydrogen could fuel Australia's next export boom after CSIRO breakthrough

Hi JM Only just looking into this and there seem to be various...

- There are more pages in this discussion • 10 more messages in this thread...

You’re viewing a single post only. To view the entire thread just sign in or Join Now (FREE)